Robert De Clercq

About us

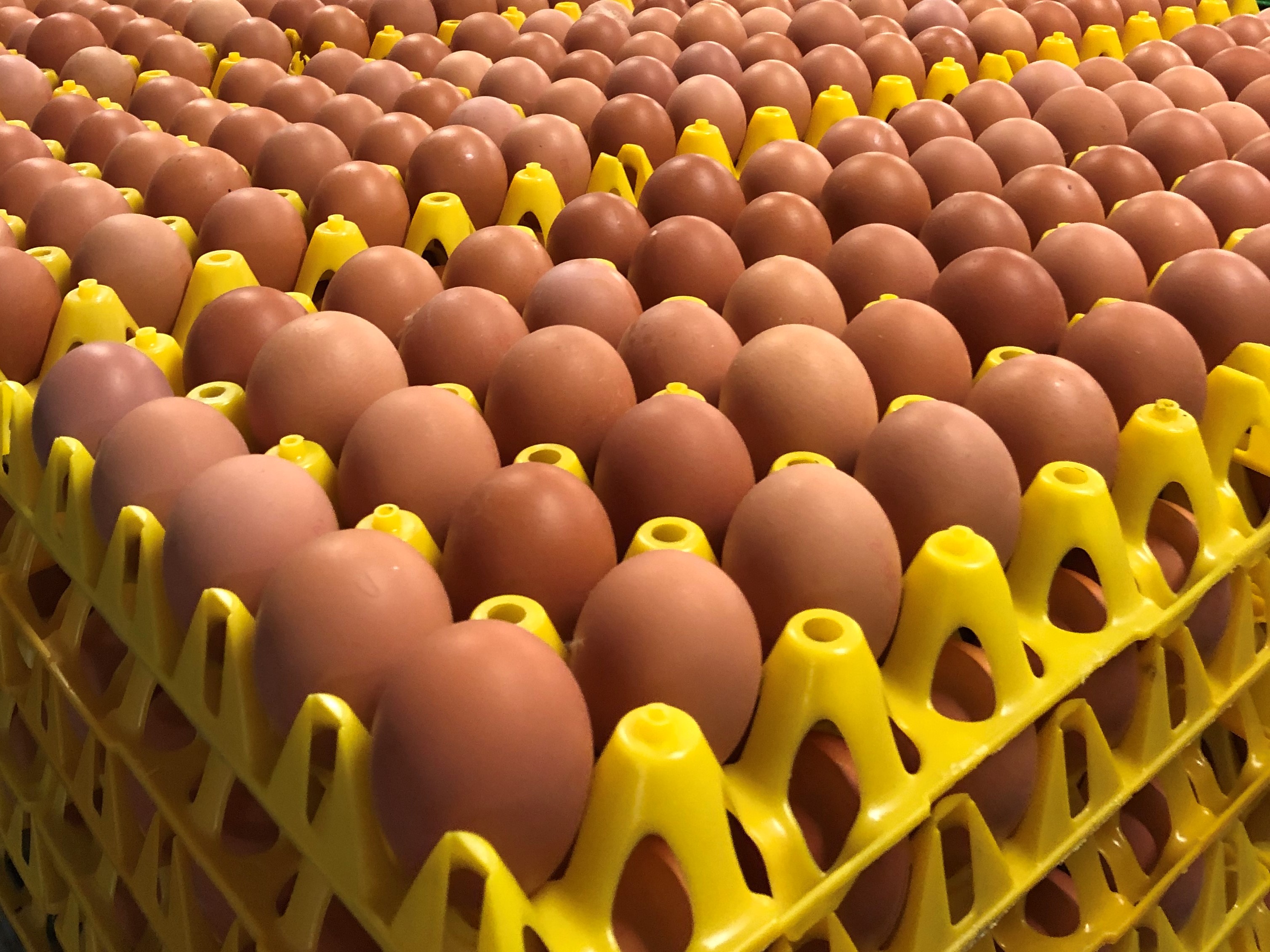

In 1960, Robert De Clercq started a small-scale, local sale of eggs. He operated from the warehouse behind his house. Due to the strong growth of the company, a move to a new distribution centre in Beigem was necessary. From then on, the export of eggs to Germany and Luxembourg became the main focus. In 1980, his children continued the company and the main activity shifted to retail, trade and sales to wholesalers and retailers.

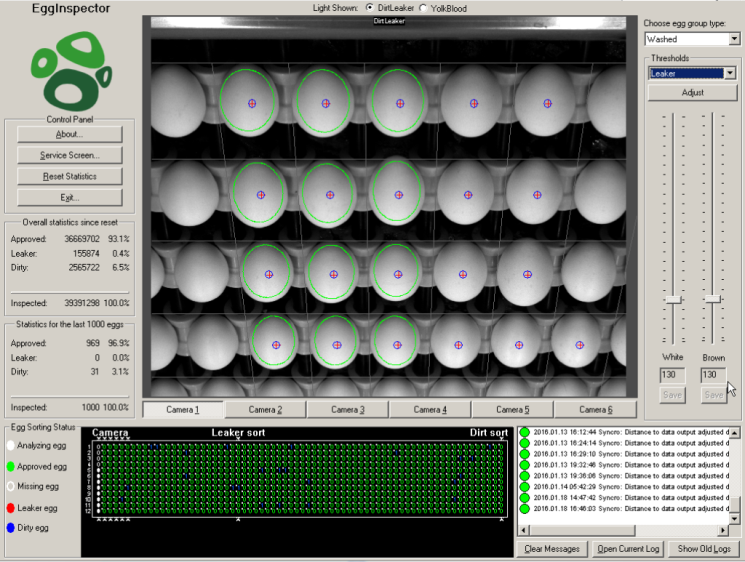

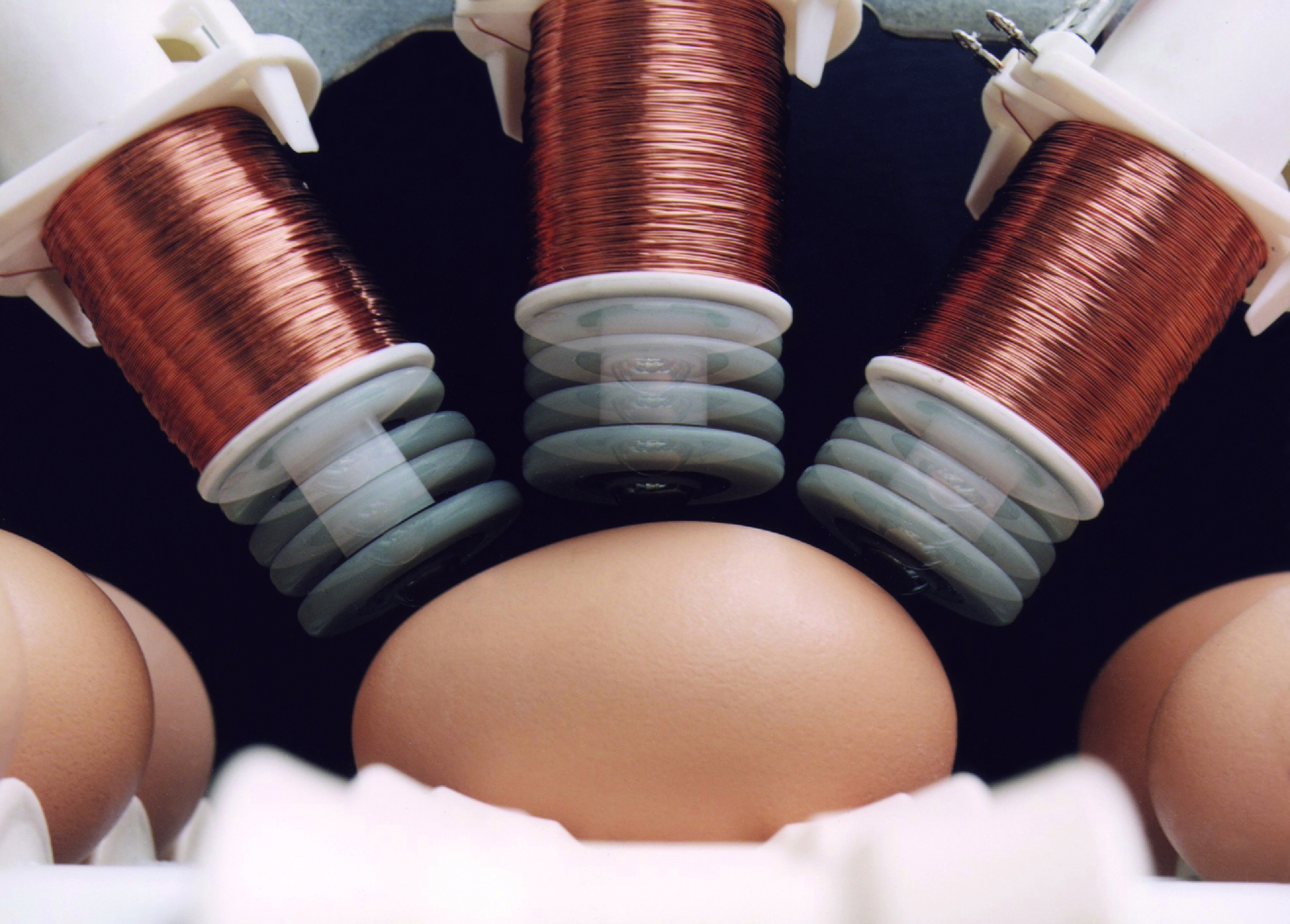

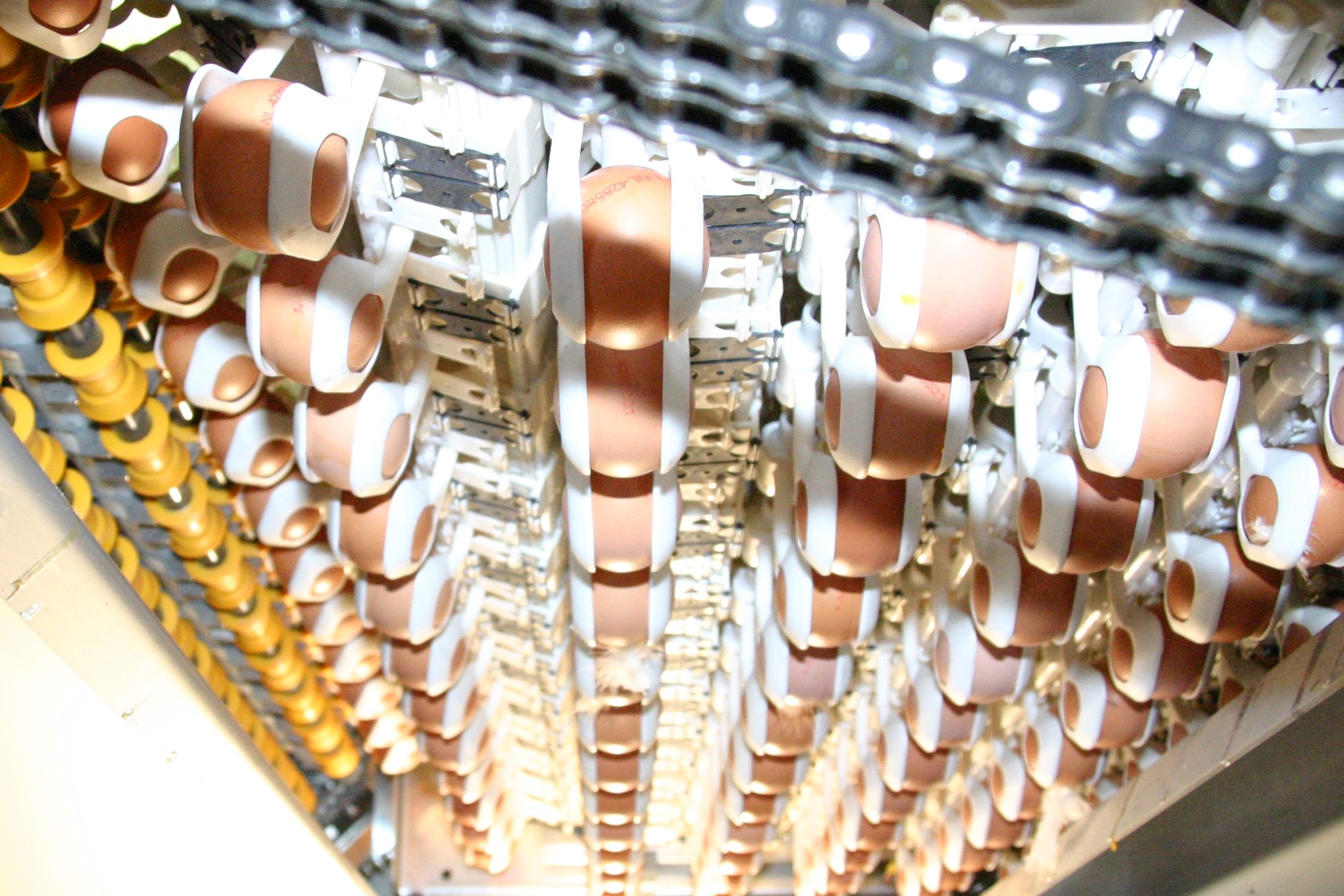

Nowadays, Hof ter Lint, under the management of Reinhilde De Clercq, is an ultra-modern packing station that works with the latest sorting techniques, where quality and hygiene are paramount. Now that her children Soetkin and Iwein have joined the company, it is a third-generation family business.